Portable vs. Fixed: Choosing the Right Gas Detector for Your Needs

Gas leaks pose serious risks to both people and property. In Malaysia, industries like oil & gas, food processing, HVAC, and manufacturing rely heavily on reliable gas detection systems to prevent accidents, ensure compliance, and safeguard workers.

Choosing between portable and fixed gas detectors is a critical step in building a safety strategy.

This guide explains the differences, benefits, and limitations of each type, integrates expert tips, and links to deeper resources like our Gas Detector FAQ on calibration, Gas Leak Detector Guide, and Choosing the Best Gas Detection System.

Why the Right Choice Matters

1. Protecting Lives and Assets

Gas detectors save lives by detecting harmful gases before they reach dangerous levels. Fires, explosions, and toxic exposures are preventable with the right system. Learn more about the importance of gas detectors and their safety benefits.

2. Compliance and Standards

Malaysian employers must follow Department of Occupational Safety and Health (DOSH) regulations, which require calibrated and well-maintained detectors. Our FAQ on calibration covers testing schedules and compliance details.

3. Operational Needs

A portable unit may suffice for confined-space entry, but factories often need fixed systems to monitor multiple points simultaneously. Understanding your environment is key.

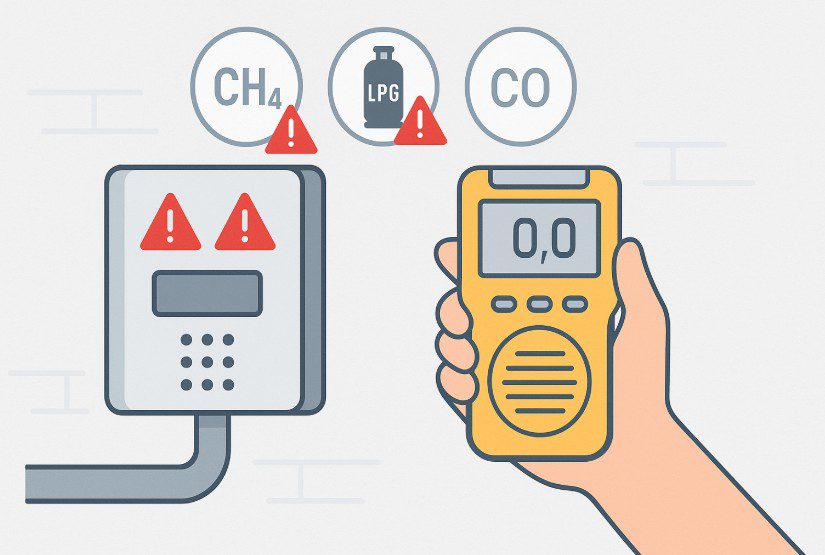

Portable Gas Detectors: Flexible, On-the-Go Safety

Key Features:

- Clip-on or handheld units that follow the worker’s breathing zone.

- Battery-powered (8–24 hours runtime), rechargeable via docking stations.

- Equipped with vibration, visual, and audible alarms.

- Ideal for confined spaces, utility inspections, and emergency responses.

Advantages:

- Flexible for workers moving across multiple job sites.

- Lower upfront cost.

- Multi-gas versions available for CO, H₂S, O₂, combustible gases, and VOCs.

Limitations:

- Require daily bump tests and frequent calibration.

- Dependent on workers using them correctly.

- Limited coverage — monitors only the immediate user’s environment.

For practical usage tips, see our Gas Leak Detector Guide.

Fixed Gas Detectors: 24/7 Area Protection

Fixed detectors are mounted in high-risk areas like production floors, chemical storage, or kitchens.

Key Features:

- Installed permanently, often 30–40 feet apart.

- Mains-powered with backup battery support.

- Can integrate with alarms, ventilation systems, or automated shutdowns.

- Provide continuous, centralized monitoring with logging functions.

Advantages:

- Continuous protection without user intervention.

- Covers wide areas, protecting multiple employees at once.

- Seamless integration with building or plant safety systems.

Limitations:

- Higher upfront investment.

- Requires proper installation and infrastructure.

- Maintenance is less frequent but more complex.

If you’re planning for a factory, lab, or commercial kitchen, check our guide on choosing the best gas detection system for business.

Portable vs. Fixed: Quick Comparison

Feature | Portable Detectors | Fixed Detectors |

Coverage | Personal, mobile | Facility-wide |

Power Source | Rechargeable battery | Mains + backup battery |

Alerts | On-device alarms | Central alarms, system integration |

Maintenance | Daily bump test + monthly calibration | Quarterly to annual calibration |

Cost | Lower upfront | Higher upfront but long-term coverage |

What They Have in Common

- Sensor Technology: Both can detect toxic gases, oxygen depletion, flammable gases, and VOCs.

- Calibration Needs: Both require periodic calibration to maintain accuracy (FAQ on calibration).

- Life-Saving Role: Regardless of format, both systems form the backbone of workplace safety.

Malaysia-Specific Considerations

- Climate: High humidity and temperature can affect sensor life, requiring more frequent checks.

- Regulatory Standards: DOSH mandates testing and proper documentation.

- Industry Use Cases:

- Portable: HVAC technicians, confined-space workers, utility crews.

- Fixed: Factories, refineries, cold storage, commercial kitchens.

For local context, our article on the importance of gas detectors in Malaysia explores common hazards and prevention.

Choosing the Right Strategy

- Go Portable If: Your workforce is mobile, works in confined spaces, or needs short-term monitoring.

- Go Fixed If: You manage plants, storage facilities, or continuous high-risk environments.

- Best Practice: Use a combination of both for maximum safety coverage.

Read our full guide on choosing the right system for your business.

Frequently Asked Questions (FAQ) About Gas Detector

What is a bump test?

A bump test checks that a detector’s sensors and alarms work properly by exposing it to a known gas. Portable detectors should be bump-tested daily. See our FAQ guide.

How often should gas detectors be calibrated?

Portable detectors: monthly calibration + daily bump tests.

Fixed detectors: quarterly to annual calibration depending on environment.

What gases can be detected?

- Electrochemical sensors: CO, H₂S.

- Infrared: CO₂ and hydrocarbons.

- Catalytic: flammable gases.

- PID: volatile organic compounds.

Why is my detector alarming even when I smell nothing?

Detectors are more sensitive than human senses. They can detect harmful gases at levels below odor thresholds.

Which is better — portable or fixed?

Neither alone is “better.” Each has its strengths. The ideal solution often combines both, ensuring workers and facilities are equally protected.

Conclusion

Portable and fixed gas detectors are complementary tools. Portable units provide personal safety in the field, while fixed systems monitor entire facilities continuously. Together, they form the backbone of a proactive safety culture.

For further resources, visit Comet Integrated — or explore our deep dives on gas detector calibration, safety benefits, gas leak detectors, and choosing the right detection system.