Natural Gas Pressure Regulator Sizing Guide: From Specifications to Installation

Gas pressure regulators play a vital role in maintaining safe and efficient gas flow across industrial, commercial, and residential applications. Proper regulator selection stands as the foundation for system stability and equipment protection.

System failures often stem from undersized regulators, leading to dangerous pressure drops and equipment malfunction during peak demand periods.

Environmental factors significantly impact regulator performance – each 1,000 feet above sea level decreases regulator capacity by 3%, making proper sizing even more crucial for high-altitude installations.

Today’s market offers numerous options, from natural gas pressure regulators to LPG variants. Selecting the right regulator demands careful evaluation of key parameters:

- Inlet pressure specifications

- Required outlet pressure range

- Maximum and minimum flow rates

- Gas type compatibility

- Safety factor requirements (20% above calculated maximum flow)

This guide examines essential aspects of gas pressure regulator selection and installation. Whether managing a single gas cylinder or implementing complex industrial systems, understanding these fundamentals helps ensure reliable gas management for your specific needs.

Read on to learn about regulator types, sizing calculations, and installation best practices.

Understanding Gas Pressure Regulator Types

Gas pressure regulators serve distinct purposes across various applications. Their design and operational characteristics determine their suitability for specific gas management needs.

Natural Gas vs LPG Regulators

Natural gas regulators maintain operational pressure at 1.1 kPa, specifically engineered for methane-based applications. LPG regulators, by contrast, function at higher pressures of 2.75 kPa.

The oxygen requirements differ significantly between these systems – LPG demands a 25:1 oxygen-to-gas ratio, while natural gas operates effectively at 10:1. These variations reflect the unique chemical properties of each gas type.

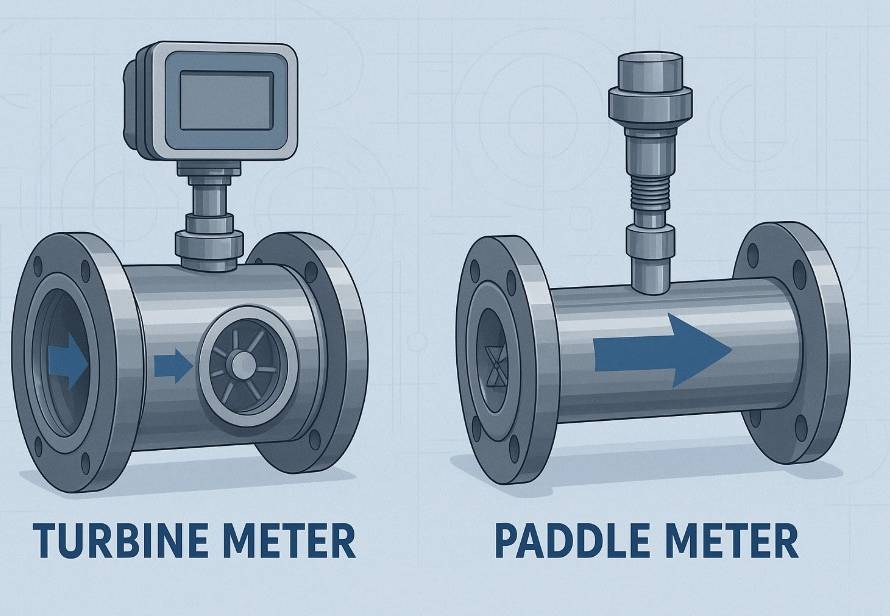

Single-Stage vs Two-Stage Regulation

Single-stage regulators perform pressure reduction in one step. These units show pressure variations of 20-40% from setpoint, making them suitable for applications where precise control proves less critical.

Two-stage regulators deliver superior pressure stability through sequential reduction:

- First stage reduces inlet pressure to intermediate levels

- Second stage achieves final desired pressure

- Maintains 1-5% offset accuracy

Direct-Acting vs Pilot-Operated Systems

Direct-acting regulators excel in applications demanding quick pressure adjustments. These units employ spring-loaded diaphragms for immediate response to downstream pressure changes.

Their straightforward design makes them ideal for simpler gas management systems.

Pilot-operated regulators offer enhanced accuracy through more sophisticated control mechanisms.

These systems utilize:

- Small pilot regulators controlling main valve operation

- External sense lines connected to downstream piping

- Superior sensitivity for precise pressure management

The choice between these systems depends primarily on application requirements, pressure ranges, and desired control precision.

Essential Sizing Parameters for Gas Regulators

Gas pressure regulator sizing demands careful attention to multiple parameters. These specifications determine system stability and flow efficiency across various operating conditions.

Maximum Inlet Pressure Requirements

Maximum inlet pressure calculations must incorporate a 10% safety margin above rated maximum pressure. Regulators perform optimally when operating within 5% of their rated outlet pressure.

Altitude significantly impacts these calculations – regulator capacity reduces by 3% with every 1,000 feet elevation gain.

Flow Rate Considerations

Proper flow rate assessment stands essential for system reliability.

The calculation process requires several key steps:

- Convert BTU/hour to cubic feet per hour (CFH) by dividing total BTU by 1,000

- Add 20% safety factor for peak demand periods

- Consider minimum flow requirements for system stability

Undersized regulators lead to pressure drops during peak demand, causing premature component wear. The smallest regulator capable of handling maximum flow requirements provides optimal control and stability.

Pressure Drop Management

Pressure drop characteristics directly influence gas flow patterns. Critical flow conditions emerge when downstream pressure falls to 50% or less of inlet pressure. Higher pressure drops create increased flow rates until reaching critical flow conditions.

Large pressure drops require staged reduction approaches rather than single-step reduction. This method helps prevent:

- System cavitation

- Excessive operational noise

- Premature component wear

Careful attention to these sizing parameters ensures reliable regulator performance across various operating conditions.

Material Selection and Safety Standards

Material selection proves crucial for gas pressure regulator performance and safety. The right materials ensure long-term reliability while meeting stringent safety requirements.

Body Material Selection

Gas properties and operating conditions dictate regulator material choices. Brass regulators deliver reliable performance for non-corrosive gasses like CO, CO2, and most hydrocarbons. Highly corrosive substances – chlorine, ammonia, and nitrogen dioxide – demand stainless steel construction.

High-purity applications benefit from barstock bodies over forged construction. These components offer:

- Reduced internal volumes enabling easier purging

- Dense grain structure resisting moisture absorption

- Enhanced surface finish limiting particle generation

Stainless steel diaphragms stand superior to elastomeric options, providing better contamination resistance and minimal off-gassing. Pure oxygen applications require specialized cleaning protocols – oil and grease must never contact these systems.

Safety Standards and Certification

Gas pressure regulators must meet ISO standards when operating at pressures up to 10 MPa with nominal diameters reaching DN 400. Service line regulators handling flow rates below 200 m³/h under normal conditions need specific certification.

LPG regulators demand compliance with established standards:

- NFPA 58 requirements

- CSA B149.1 specifications

- Automatic shut-off mechanisms for overpressure protection

While regulators without electrical components may skip mandatory testing, independent inspection remains vital for system safety. These standards ensure reliable operation across various applications.

Gas Pressure Regulator Selection Guidelines

Gas pressure regulator installation specifications determine system reliability and performance. These requirements prevent common errors while ensuring optimal operation.

Mounting Position Requirements

Modern gas pressure regulators accommodate multiple mounting positions. Regulators with vent limiting devices must maintain horizontal upright positioning. Propane system installations demand either downward-pointing regulators or adapters directing vent openings downward.

Piping Configuration Specifications

Proper piping arrangements directly influence regulator effectiveness. The system requires:

- Minimum 6 pipe diameters of straight pipe downstream, free from turbulence-generating equipment

- 10 pipe diameters separation between upstream and downstream regulators in monitor stations

Pipe sizing guidelines specify:

- Standard pipe sizes ranging from ½-inch to 4-inches affect flow capacity

- Outlet piping diameter exceeding regulator size

- Straight pipe runs extending 6 diameters downstream for control line connections

Vent Line Requirements

Vent line installation demands precise safety considerations. Key specifications include:

- Vent termination points minimum 3 feet from ignition sources

- Special antiflood-type breather vent fittings for flood-prone locations

- Vent line extension above anticipated flood levels

Vent openings need protection against environmental factors:

- Rain and snow accumulation

- Ice formation prevention

- Foreign material blockage

These specifications ensure reliable regulator performance while maintaining system safety.

Applications of Gas Pressure Reducing Regulators

Gas pressure regulators perform essential functions across numerous industries. Each sector demands specific operational parameters and safety requirements.

Power Generation Applications

Power facilities rely on pilot-operated regulators for precise natural gas flow control. These systems manage transmission pipeline pressures from 200 psig to over 1000 psig. Modern regulators achieve set pressure accuracy between 0.5% to 2.5%.

Process Industry Requirements

Petrochemical and oil sectors depend on regulators for complex gas train operations and refinery processes. Medical settings demand exceptional precision – particularly for anesthesia delivery systems and oxygen supply networks where patient safety proves critical.

Industrial Applications

Industrial environments utilize regulators for multiple purposes:

- Manufacturing process gas control

- Single-stage regulation in welding operations

- Two-stage systems for laboratory precision

- Dome-loaded regulators for high-flow needs

Commercial and Residential Uses

Residential systems employ regulators to maintain safe natural gas appliance operation. Commercial installations typically feature medium-pressure regulators designed for fuel gas systems. Industrial facilities benefit from low-pressure industrial regulators, built rugged for demanding conditions.

Gas pressure regulators deliver significant operational benefits. These devices optimize fuel consumption in heating applications, reducing energy costs. High-altitude installations require special pressure adjustments to compensate for atmospheric conditions.

Through reliable pressure control, these devices protect equipment while ensuring steady gas delivery across diverse applications.

Installation Requirements and Best Practices

Gas pressure regulator installation demands strict adherence to safety protocols and maintenance procedures.

Technicians must wear appropriate PPE and follow company safety policies. Each regulator requires thorough component inspection before assembly, checking for damage, contamination, or wear.

Essential Installation Steps

Leak testing proves crucial after initial installation. Technicians must apply approved leak detection solutions to pressurized joints and connections. Oxygen systems demand specialized leak detection products – standard soap solutions create fire hazards.

Maintenance Requirements

Regular maintenance schedules should include:

- Annual flashback arrestor inspection on flammable gas cylinders

- Visual examination of gas line components

- Testing of automatic shut-off mechanisms

- Regulator replacement every five years under standard conditions

Safety Protocols

Regulators demand strict cleanliness standards – keep all components free from oil, grease, and contaminants. Oxygen regulators require fluorescent light inspection for grease detection. System purging with dry inert gas must precede hazardous gas introduction.

Installation Specifications

Proper vent positioning prevents moisture infiltration. Vent line sizing requires one nominal size increase per 10 feet of length. Control lines need minimum 3/8-inch diameter tubing for optimal performance.

Gas flow direction must match regulator body arrows. System startup procedures include:

- Removal of all shipping plugs

- Verification of debris-free piping interiors

- Installation of downstream pressure gauges for system monitoring

These requirements ensure safe, efficient regulator operation while maximizing system longevity.

Conclusion

Gas pressure regulators serve as cornerstone components in modern gas management systems. Their proper selection and installation safeguard equipment while delivering consistent gas flow across diverse applications.

Successful gas pressure regulation depends on several key factors. Understanding regulator varieties – from basic single-stage units to sophisticated pilot-operated systems – enables precise matching with specific applications.

Proper sizing calculations, including the essential 20% safety factor and altitude adjustments, prevent costly system failures and equipment damage.

Material choices significantly impact regulator performance and longevity. Demanding environments and corrosive gases require stainless steel construction, while standard applications perform well with brass regulators.

Safety standards compliance, particularly with NFPA 58 and CSA B149.1, ensures reliable system operation.

Regular maintenance routines protect system integrity:

- Scheduled component inspections

- Systematic leak testing procedures

- Timely replacement of worn parts

- Proper mounting position verification

- Correct piping configuration maintenance

Gas pressure regulators maintain their vital role across multiple sectors:

- Power generation facilities

- Petrochemical processing plants

- Medical gas systems

- Residential gas networks

These devices excel at maintaining precise pressure control while protecting valuable downstream equipment.

The guidelines presented here help achieve optimal gas pressure regulation for any application, ensuring both safety and efficiency in gas management operations.

Frequently Asked Questions about Gas Pressure Regulator

When selecting a gas pressure regulator, consider the inlet and outlet pressure ranges, required flow rate, type of gas (including toxicity and flammability), expected operating temperature range, and material compatibility. Also, factor in size and weight constraints for your specific application.

The correct size of a gas pressure regulator is primarily determined by the required flow rate in your system. Larger regulators can handle higher flows while effectively controlling pressure, whereas smaller regulators are suitable for lower-flow velocities. It’s important to select a regulator that can handle your maximum flow requirement while ensuring optimal control and stability.

Material selection is crucial for regulator performance and safety. For non-corrosive gasses, brass regulators are often suitable. However, corrosive gasses or high-purity applications may require stainless steel construction. The choice of materials affects the regulator’s resistance to contamination, durability, and overall performance in specific operating conditions.

Gas pressure regulators should undergo annual inspections, including checks on flashback arrestors for flammable gas cylinders. Regular visual inspections of gas line components are also recommended. Under normal use, it’s advisable to replace regulators every five years to ensure continued safe and efficient operation.

Critical installation requirements include proper mounting position, adequate upstream and downstream piping, and correct vent line installation. Ensure at least 6 pipe diameters of straight pipe downstream of the regulator, free from turbulence-generating equipment. Vent lines should terminate at least 3 feet from any ignition source and be protected against environmental factors. Always perform leak testing after installation using appropriate methods for the specific gas type.